Fiber Plastic Geogrid

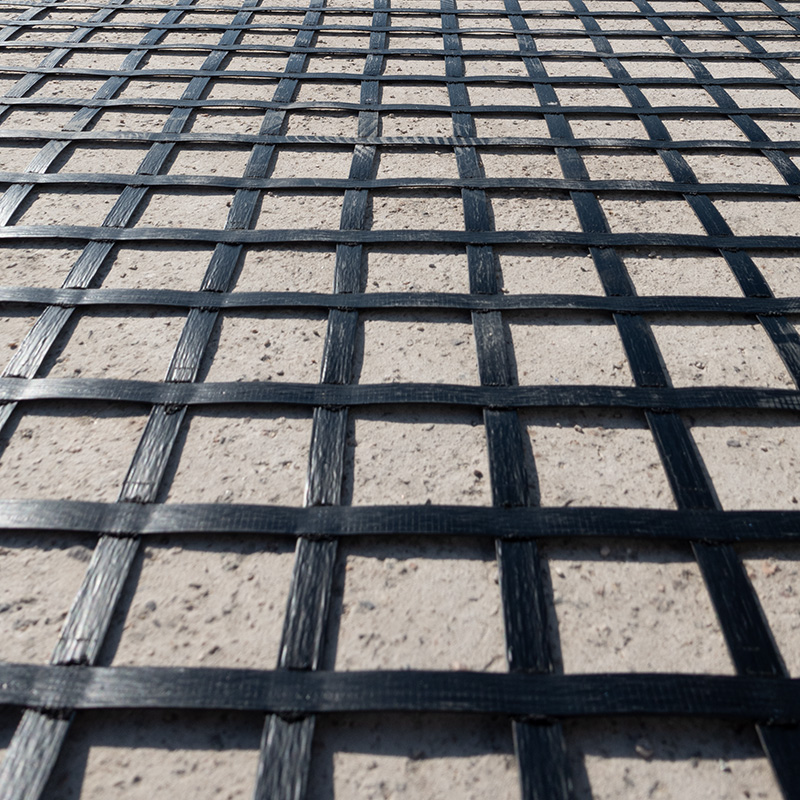

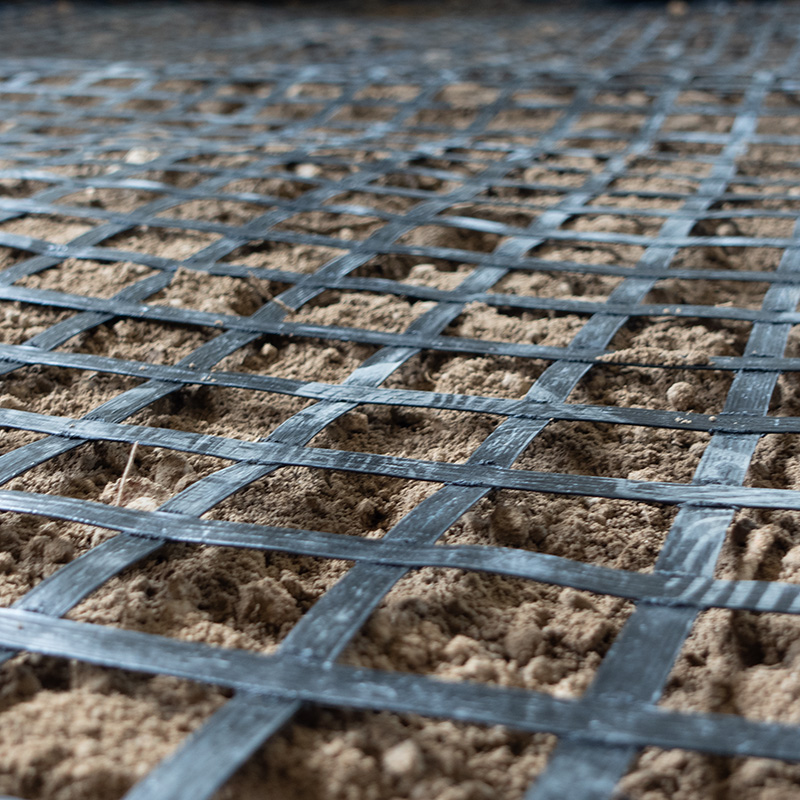

Fiber plastic geogrid is made of polymer plastic and high-strength fiber composite, which has both corrosion resistance and high tensile strength. It is widely used in highway, railway and other engineering projects to enhance foundation stability and extend service life.

PRODUCT DETAILS

Product Features

1、High strength tensile performance

Using fiber reinforcement technology, it has high longitudinal and transverse tensile strength, which can effectively disperse loads and prevent soil cracking and settlement.

2、Excellent corrosion resistance

Acid and alkali resistant, salt resistant, suitable for harsh environments such as coastal areas, saline soils, and landfills.

3、Excellent flame retardant performance

Adding high-efficiency flame retardants to meet national flame retardant standards, effectively reducing fire risks, suitable for places with high fire prevention requirements such as tunnels and mines.

4、Anti aging, long service life

Adding anti UV agents has strong antioxidant properties and is not easy to age after long-term outdoor use.

5、Low elongation, high modulus

Small deformation can effectively constrain soil displacement and improve the overall stability of engineering structures.

6、Strong permeability and good drainage performance

The mesh structure ensures free water infiltration and avoids soil softening caused by water accumulation.

7、Convenient construction, economical and efficient

Lightweight, easy to transport and lay, can be cut on site, adapts to different engineering needs, and reduces construction costs.

Specification and technical indicators of Fiber Plastic Geogrid

| Item | RMXS TGSG50-50 | RMXS TGSG100-100 | RMXS TGSG150-150 | RMXS TGSG200-200 |

|---|---|---|---|---|

| Width m | 2m, 4m, 6m (customizable according to customer needs, with a maximum width of 6m) | |||

| Length m | 30m, 50m (customizable according to customer needs, unlimited length) | |||

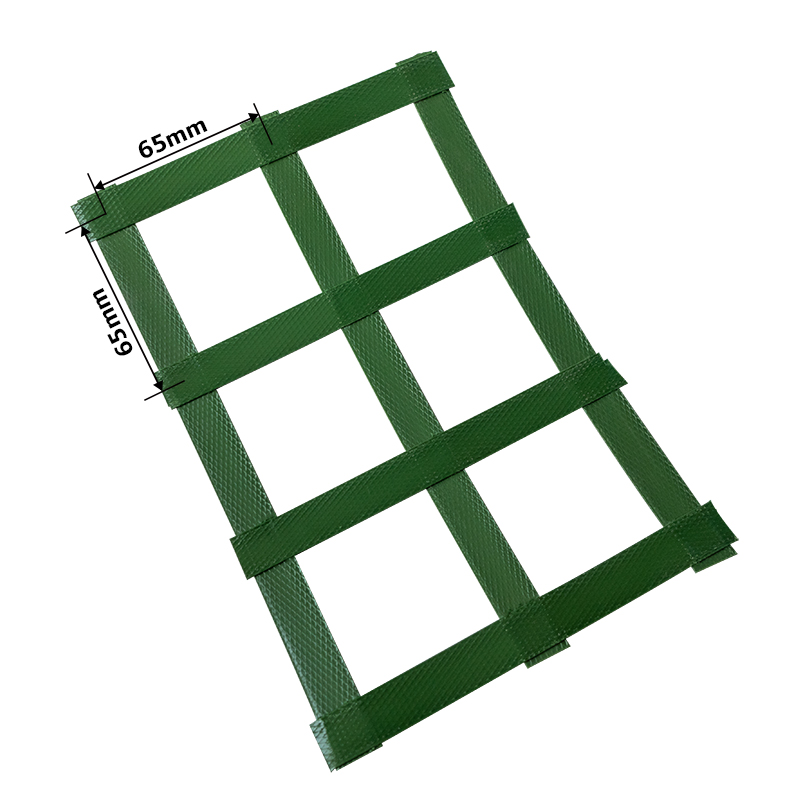

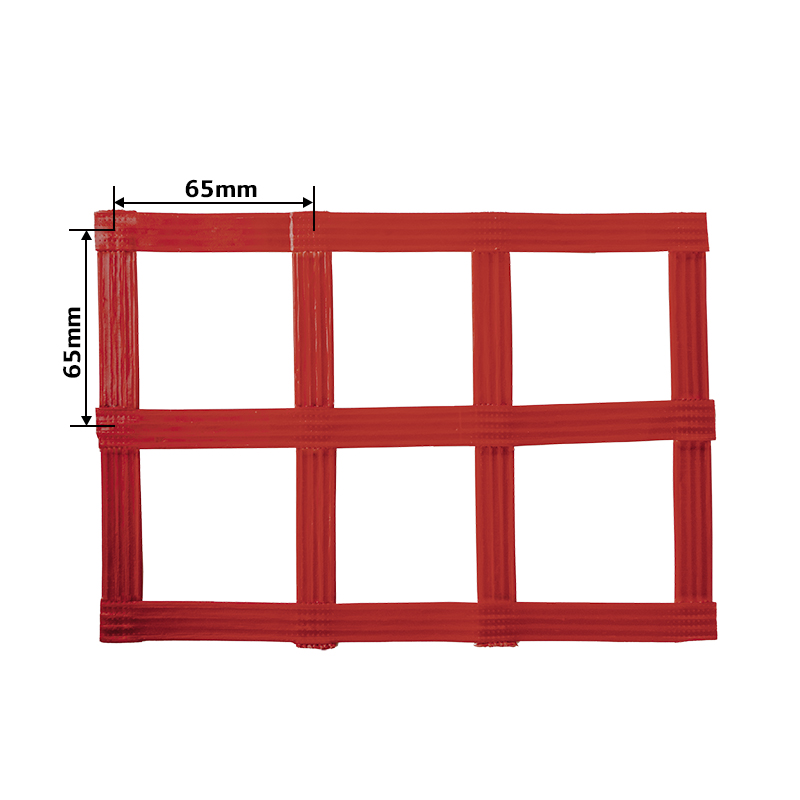

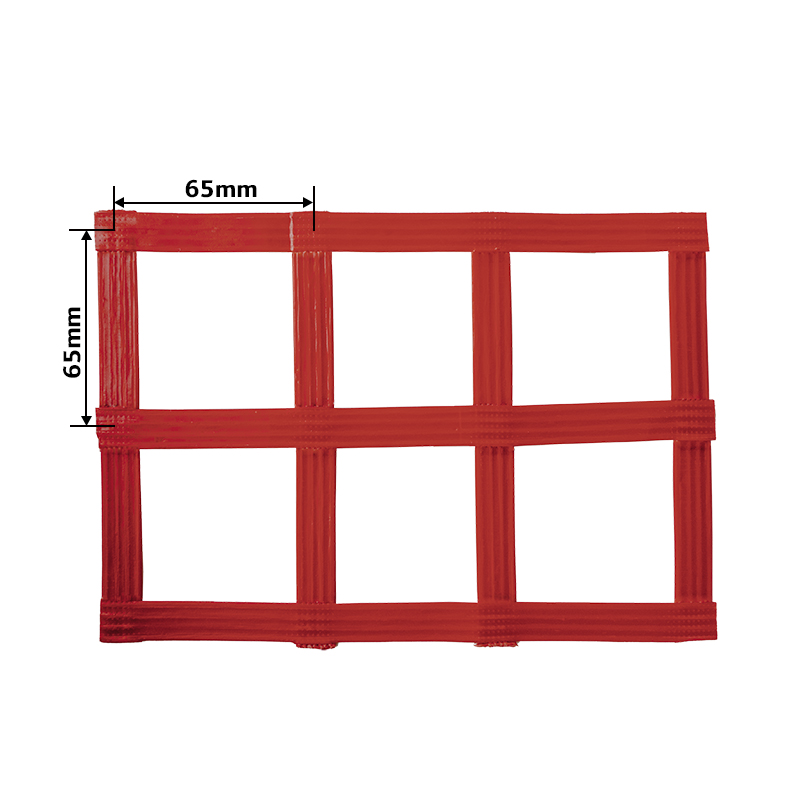

| Mesh size (also known as cell size) mm | 65mm (strip to medium size, including the width of one strip) | |||

| Colour | Black, Blue, Green (customizable according to customer needs) | |||

| Ultimate tensile strength per linear meter in both longitudinal and transverse directions (kN/m) | ≥50 | ≥100 | ≥150 | ≥200 |

| Elongation percentage at nominal tensile strength in both longitudinal and transverse directions | ≤16 | ≤16 | ≤16 | ≤16 |

| Tensile force kN/m at 2% elongation in both longitudinal and transverse directions | ≥17 | ≥35 | ≥52 | ≥69 |

| Tensile force kN/m at 5% elongation in both longitudinal and transverse directions | ≥34 | ≥70 | ≥104 | ≥138 |